Tungsten Carbide Rings

Hyperion Materials & Technologies offers a wide range of tungsten carbide rings for use in steel production and rolling mill applications. Tungsten carbide provides a unique combination of strength, hardness, and toughness bringing optimal wear resistance to the rings uniquely designed to withstand a very demanding production environment. These material properties play a critical role in significantly increasing performance by reducing line stops and contributing to higher productivity from rolling mills.

Hyperion manufactures tungsten carbide rings made of cemented tungsten carbide for finishing blocks or to be mounted in rolls for use in intermediate, pre-finishing, and finishing stands for rolling mill applications.

产品分类

Hyperion Code: CIC-Cantilever

Description: Tungsten carbide layer bonded to a cast iron ring. The carbide/steel ring mounts to an arbor through a mechanical clamping/locking system.

Hyperion Code: CIC-Tube

Description: Tungsten carbide layer bonded to a cast iron core. Designed for operation in tube mill applications.

Hyperion Code: CIC-Composite

Description: Tungsten carbide layer bonded to a cast iron ring. Designed for use with composite rolls.

Hyperion Code: CIC-Cantilever

Description: Tungsten carbide layer bonded to a cast iron ring. The carbide/steel ring mounts to an arbor through a mechanical clamping/locking system.

Hyperion Code: CIC-Tube

Description: Tungsten carbide layer bonded to a cast iron core. Designed for operation in tube mill applications.

Hyperion Code: CIC-Composite

Description: Tungsten carbide layer bonded to a cast iron ring. Designed for use with composite rolls.

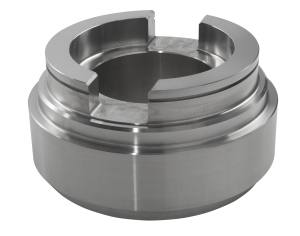

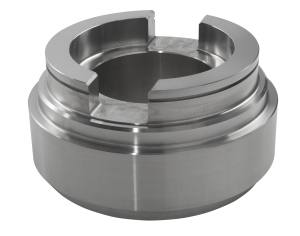

Solid Tungsten Carbide Rings

Solid tungsten carbide rings provide great durability for use in rolling mills. They are made from the highest quality tungsten carbide and are resistant to wear, corrosion, and heat. Solid tungsten carbide rings can withstand the harshest conditions in rolling mills and will last for many years.

In addition to their durability, solid tungsten carbide rings are also very precise. They can be machined to exact specifications, which ensures that they will fit perfectly in your rolling mill.

Cast-in-Carbide (CIC®) Rings

Cast-in-carbide, or CIC®, rings are a type of wear-resistant ring that is made by bonding a layer of tungsten carbide to a cast iron ring. The tungsten carbide layer is very hard and wear-resistant, while the cast iron ring provides strength and toughness. This combination of properties makes CIC® rings ideal for applications where high wear resistance is required, such as in the rolling mills and metalworking industries.

CIC® rings offer a number of benefits, including:

• High wear resistance

• Strength and toughness

• Long service life

• Low maintenance

• No risk of material separation

FAQs about Carbide Rings

CIC® rings are made by bonding a layer of tungsten carbide to a cast iron ring. The carbide layer provides greater strength and wear resistance, extending the service life of the ring. Because the tungsten carbide is bonded to the cast iron, the risk of material separation is eliminated.

Tungsten carbide rings and CIC™ rings can be use in the finishing blocks, sizing units, composite rolls, cantilever stands, tube stretch reducing mills (SRM) for long product steel rolling mills.

Hyperion's tungsten carbide rings provide up to 20 times the wear resistance of traditional cast iron rolls. This can translate into a considerable reduction of stoppage time for the rolling mill and increased mill output.

Hyperion tungsten carbide rings can be tailor made to fit into existing applications.

Hyperion carbide roll product specialists can partner with you to determine the best grade for each application and tailor solutions to your specific needs.

Converting from cast iron to tungsten carbide can considerably increased rolled tonnage by up to 20 times leading to higher productivity and lower operational costs.